Fill Out a Valid Welder Performance Qualification Record Template

Guide to Writing Welder Performance Qualification Record

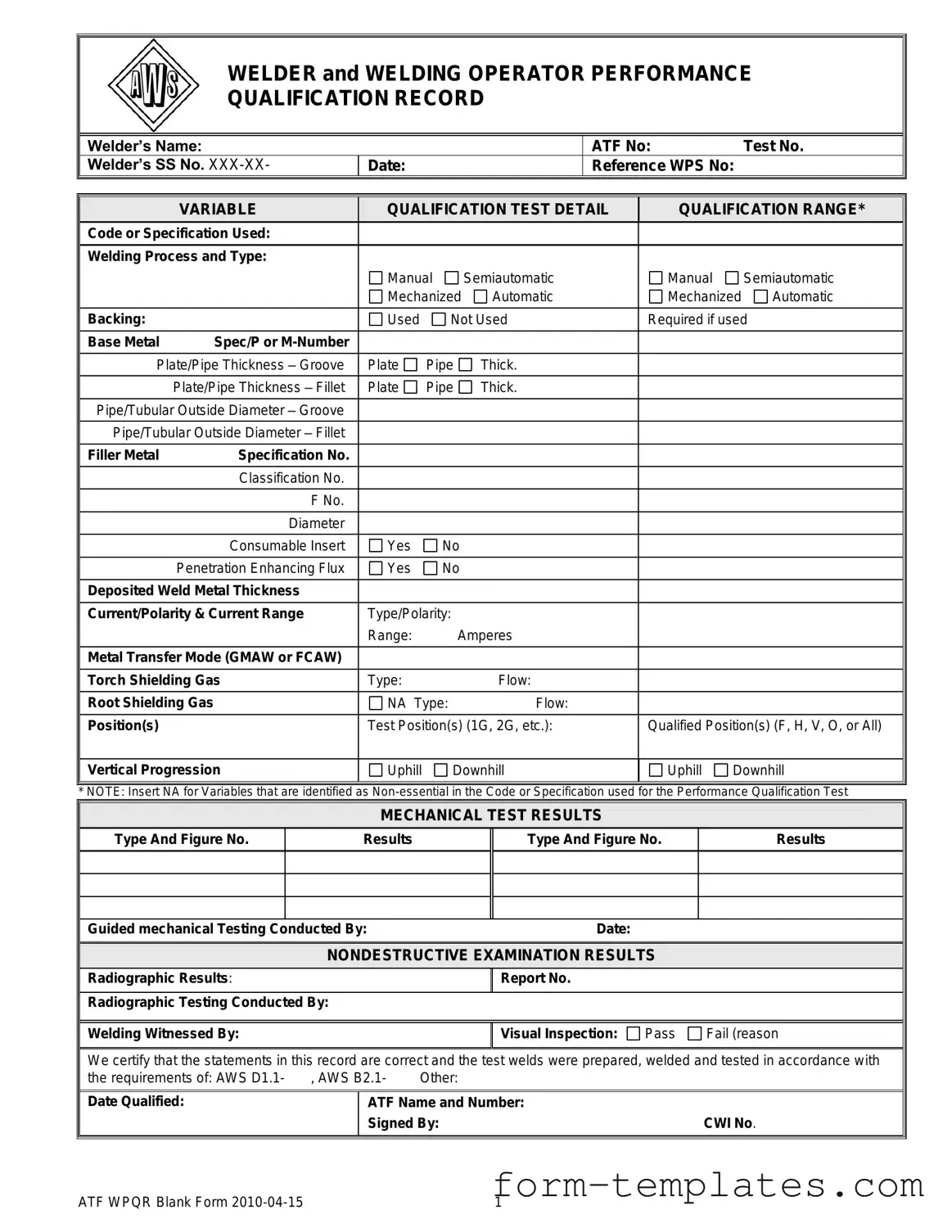

Completing the Welder Performance Qualification Record form is an essential step in documenting a welder's skills and qualifications. This form captures various details about the welder, the testing process, and the results. Follow these steps to accurately fill out the form.

- Welder’s Information: Enter the welder’s name, ATF number, test number, and Social Security number. Include the date of completion.

- Reference WPS Number: Fill in the reference Welding Procedure Specification (WPS) number.

- Qualification Test Details: Specify the code or specification used for the qualification.

- Welding Process and Type: Indicate the welding process (manual, semiautomatic, mechanized, or automatic) and check whether backing was used or required.

- Base Metal Specifications: Provide the specification or P/M number, and indicate the plate or pipe thickness for both groove and fillet welds.

- Pipe/Tubular Dimensions: Enter the outside diameter for both groove and fillet pipe or tubular welds.

- Filler Metal Information: Fill in the filler metal specification number, classification number, and diameter. Indicate if a consumable insert or penetration enhancing flux was used.

- Deposited Weld Metal Thickness: Record the thickness of the deposited weld metal.

- Current and Polarity: Specify the type and polarity of the current, including the range in amperes.

- Metal Transfer Mode: Indicate the metal transfer mode (GMAW or FCAW).

- Torch Shielding Gas: Enter the type and flow rate of the torch shielding gas. If root shielding gas was used, specify the type and flow rate.

- Test Positions: List the test positions (e.g., 1G, 2G) and the qualified positions (F, H, V, O, or All).

- Progression: Indicate the vertical progression method (uphill or downhill).

- Mechanical Test Results: Record the type and figure number of the mechanical tests conducted, along with the results.

- Non-destructive Examination Results: Document the radiographic results, including the report number and who conducted the testing. Note the visual inspection results (pass or fail) and provide reasons if applicable.

- Certification: Certify the accuracy of the statements in the record. Include the date qualified, the ATF name and number, and the signature of the Certified Welding Inspector (CWI) along with their number.

Document Breakdown

| Fact Name | Description |

|---|---|

| Purpose | The Welder Performance Qualification Record form is used to document a welder's qualifications and skills in various welding processes. |

| Essential Information | This form requires key details such as the welder’s name, test number, and the specific welding processes used during qualification. |

| Governing Standards | The qualifications must adhere to standards such as AWS D1.1 and AWS B2.1, which outline the requirements for welding performance. |

| Test Results | Results from mechanical tests and non-destructive examinations must be included to validate the welder's skills and the quality of the welds. |

| Certification | After completing the necessary tests, the form must be signed by a Certified Welding Inspector (CWI) to certify the accuracy of the record. |

FAQ

What is the purpose of the Welder Performance Qualification Record form?

The Welder Performance Qualification Record form serves as a formal documentation tool that verifies a welder's skills and qualifications. It records the specific tests a welder has completed and the results of those tests. This information is crucial for employers and regulatory bodies to ensure that the welder meets the required standards for safety and quality in welding operations.

Who needs to complete this form?

This form must be completed by welders and welding operators who are seeking to demonstrate their proficiency in various welding processes. It is particularly important for those working in industries where compliance with specific codes and standards, such as AWS (American Welding Society), is mandatory. Employers may also require this documentation to ensure their workforce meets industry standards.

What information is required on the form?

The form requires several key pieces of information, including:

- Welder's name and identification numbers (such as ATF and Social Security numbers)

- Date of the qualification test

- Reference WPS (Welding Procedure Specification) number

- Details about the welding process used, including type and position

- Results of mechanical tests and non-destructive examinations

All of this information helps to create a comprehensive profile of the welder's capabilities.

What types of welding processes are covered?

The form accommodates various welding processes, including manual, semiautomatic, mechanized, and automatic methods. Specific details about the type of welding performed, such as GMAW (Gas Metal Arc Welding) or FCAW (Flux-Cored Arc Welding), are also documented. This allows for a clear understanding of the welder's expertise across different techniques.

What are the mechanical test results?

Mechanical test results refer to the evaluations conducted to assess the strength and integrity of the welds produced by the welder. These tests can include tensile tests, bend tests, and impact tests, among others. The results are recorded on the form, providing evidence of the welder's ability to produce welds that meet specified standards.

What does the non-destructive examination involve?

Non-destructive examination (NDE) is a critical part of the qualification process. It involves testing methods such as radiographic inspection to evaluate the quality of the welds without damaging them. The results of these examinations are documented on the form, indicating whether the welds passed or failed inspection. This process ensures that any defects are identified before the welds are put into service.

How long is the qualification valid?

The validity of the qualification can vary based on industry standards and specific employer requirements. Generally, qualifications may need to be renewed periodically, especially if there are changes in welding processes, materials, or codes. It is essential for welders to stay informed about the duration of their qualifications and any necessary re-testing.

Who certifies the information on the form?

The information on the Welder Performance Qualification Record form is certified by a qualified individual, typically a Certified Welding Inspector (CWI). This person verifies that the tests were conducted according to the applicable codes and standards. Their signature on the form adds credibility to the qualification record and assures employers of its authenticity.

Fill out Other Forms

Puppy Health Record - Type of vaccine ensures proper health coverage.

The Employee Availability form is a document designed to capture the preferred working hours and availability of employees. This form serves as a vital tool for employers in scheduling shifts and ensuring that staffing needs are met efficiently. To streamline the process, consider filling out the form by clicking the button below or accessing the Employee Availability Form for more details.

Roof Certificate of Completion - It is advisable for homeowners to check their insurance company's requirements for this form.

Welder Performance Qualification Record Example

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

|

Welder’s Name: |

|

|

|

|

ATF No: |

|

Test No. |

||||||

|

Welder’s SS No. |

|

Date: |

|

|

Reference WPS No: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

VARIABLE |

|

|

QUALIFICATION TEST DETAIL |

|

|

QUALIFICATION RANGE* |

|

|||||

|

Code or Specification Used: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Welding Process and Type: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Manual |

Semiautomatic |

|

|

Manual |

|

Semiautomatic |

|||

|

|

|

|

|

Mechanized |

Automatic |

|

|

Mechanized |

Automatic |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Backing: |

|

|

|

Used |

Not Used |

|

|

Required if used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

Spec/P or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Plate/Pipe Thickness – Groove |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Plate/Pipe Thickness – Fillet |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Groove |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Fillet |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Metal |

Specification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Classification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Consumable Insert |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Penetration Enhancing Flux |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Deposited Weld Metal Thickness |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Current/Polarity & Current Range |

|

Type/Polarity: |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Range: |

Amperes |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Metal Transfer Mode (GMAW or FCAW) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Torch Shielding Gas |

|

Type: |

|

Flow: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

Root Shielding Gas |

|

NA Type: |

Flow: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

Position(s) |

|

|

|

Test Position(s) (1G, 2G, etc.): |

|

|

Qualified Position(s) (F, H, V, O, or All) |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Vertical Progression |

|

Uphill |

Downhill |

|

|

Uphill |

Downhill |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTE: Insert NA for Variables that are identified as

|

|

|

|

MECHANICAL TEST RESULTS |

|

|

||

|

Type And Figure No. |

|

|

Results |

|

Type And Figure No. |

Results |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided mechanical Testing Conducted By: |

|

Date: |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

NONDESTRUCTIVE EXAMINATION RESULTS |

|

|

|||

|

Radiographic Results: |

|

|

|

Report No. |

|

|

|

|

|

|

|

|

|

|

||

|

Radiographic Testing Conducted By: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Witnessed By: |

|

|

|

Visual Inspection: Pass |

Fail (reason |

) |

|

|

|

|

|

|||||

|

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with |

|||||||

|

the requirements of: AWS D1.1- |

, AWS B2.1- |

Other: |

|

|

|||

|

|

|

|

|

|

|||

|

Date Qualified: |

|

ATF Name and Number: |

|

|

|||

|

|

|

|

Signed By: |

CWI No. |

|

||

|

|

|

|

|

|

|

||

ATF WPQR Blank Form |

|

|

1 |

|

|

|||