Fill Out a Valid Pre Trip Inspection Checklist Template

Guide to Writing Pre Trip Inspection Checklist

Completing the Pre Trip Inspection Checklist form is an important step before hitting the road. It ensures that all necessary checks are made to keep you and others safe. Follow these steps carefully to fill out the form correctly.

- Begin by writing the date at the top of the form.

- Fill in your name and the vehicle identification number (VIN).

- Check each section of the checklist, which may include items like lights, brakes, tires, and fluid levels.

- For each item, mark it as “OK” if it is in good condition or “NOT OK” if it needs attention.

- If you mark any item as “NOT OK,” provide a brief description of the issue in the comments section.

- Sign and date the form at the bottom to confirm that the inspection has been completed.

Document Breakdown

| Fact Name | Description |

|---|---|

| Purpose | The Pre Trip Inspection Checklist is designed to ensure that vehicles are safe and operational before they are used on the road. |

| Components | The checklist typically includes sections for checking brakes, lights, tires, and fluid levels. |

| Frequency | Drivers are required to complete the checklist before each trip to promote safety and compliance. |

| Documentation | Completed checklists must be kept on file for a specified period, often required for inspections and audits. |

| Regulatory Compliance | Federal Motor Carrier Safety Administration (FMCSA) regulations mandate the use of a Pre Trip Inspection Checklist. |

| State-Specific Laws | Each state may have additional requirements for the Pre Trip Inspection Checklist, governed by local transportation laws. |

| Training | Drivers must receive training on how to properly complete the checklist and identify potential issues. |

FAQ

What is the Pre Trip Inspection Checklist form?

The Pre Trip Inspection Checklist form is a document used by drivers to ensure that their vehicle is safe and ready for operation before beginning a trip. It outlines various components and systems of the vehicle that need to be checked, promoting safety and compliance with regulations.

Why is a Pre Trip Inspection important?

A Pre Trip Inspection is crucial for several reasons. First, it helps identify potential mechanical issues that could lead to breakdowns or accidents. Second, it ensures that the vehicle meets safety standards and regulatory requirements. Lastly, it protects both the driver and other road users by ensuring that the vehicle is in good working condition.

Who is responsible for completing the Pre Trip Inspection Checklist?

The driver of the vehicle is primarily responsible for completing the Pre Trip Inspection Checklist. It is their duty to ensure that the vehicle is safe for operation. However, fleet managers and maintenance personnel may also play a role in reviewing the checklist and ensuring compliance with safety standards.

What items are typically included in the Pre Trip Inspection Checklist?

The checklist usually covers a range of items, including:

- Tires: Checking for proper inflation and tread depth.

- Brakes: Ensuring that the brake system functions correctly.

- Lights: Verifying that all headlights, brake lights, and turn signals are operational.

- Fluid Levels: Checking oil, coolant, and brake fluid levels.

- Wipers: Ensuring that windshield wipers are functioning and that the washer fluid is full.

- Mirrors: Confirming that all mirrors are properly adjusted and free of obstructions.

How often should the Pre Trip Inspection be conducted?

The Pre Trip Inspection should be conducted before every trip. This practice ensures that the vehicle is safe and ready for the journey ahead. Regular inspections help maintain the vehicle's performance and reliability over time.

What should a driver do if they find an issue during the inspection?

If a driver identifies any issues during the Pre Trip Inspection, they should not operate the vehicle until those issues have been resolved. The driver should report the problem to the appropriate personnel, such as a fleet manager or maintenance team, who can assess and fix the issue before the trip begins.

Is there a specific format for the Pre Trip Inspection Checklist?

While there is no universally mandated format, many companies and organizations create their own checklists tailored to their vehicles and operational needs. These checklists should be clear, comprehensive, and easy to follow, ensuring that all necessary checks are completed.

Can electronic devices be used for the Pre Trip Inspection?

Yes, many drivers now use electronic devices and applications to conduct their Pre Trip Inspections. These digital tools can streamline the process, making it easier to document findings and track maintenance records. However, it is essential to ensure that any electronic method complies with regulatory requirements.

What happens if a driver fails to complete the Pre Trip Inspection?

Failing to complete the Pre Trip Inspection can lead to serious consequences. The driver may face disciplinary action from their employer, and they could be held liable for any accidents or incidents that occur due to mechanical failure. Additionally, regulatory agencies may impose fines for non-compliance with inspection requirements.

Where can I find a sample Pre Trip Inspection Checklist?

Sample Pre Trip Inspection Checklists can often be found online through transportation and safety organizations. Many trucking companies also provide templates for their drivers. It is advisable to use a checklist that aligns with industry standards and specific vehicle requirements.

Fill out Other Forms

Annual Vehicle Inspection Report - The certified inspector's name must be printed or typed for accountability.

Emotional Support Animal Letter From Therapist - The presence of an emotional support animal can create a calming effect during distress.

The importance of the Work Release form extends beyond mere documentation; it represents an opportunity for growth and rehabilitation. For many individuals, understanding this form is crucial as it permits them to work outside their detention facility, facilitating a smoother transition back into society. Resources such as the Work Release Form can provide valuable insights and guidance on how to complete the process effectively, ensuring that individuals are better prepared to meet both their employment and legal obligations.

USCIS Form I-864 - Timing for submitting the I-864 is critical for the overall process timeline.

Pre Trip Inspection Checklist Example

Class A CDL

®

®

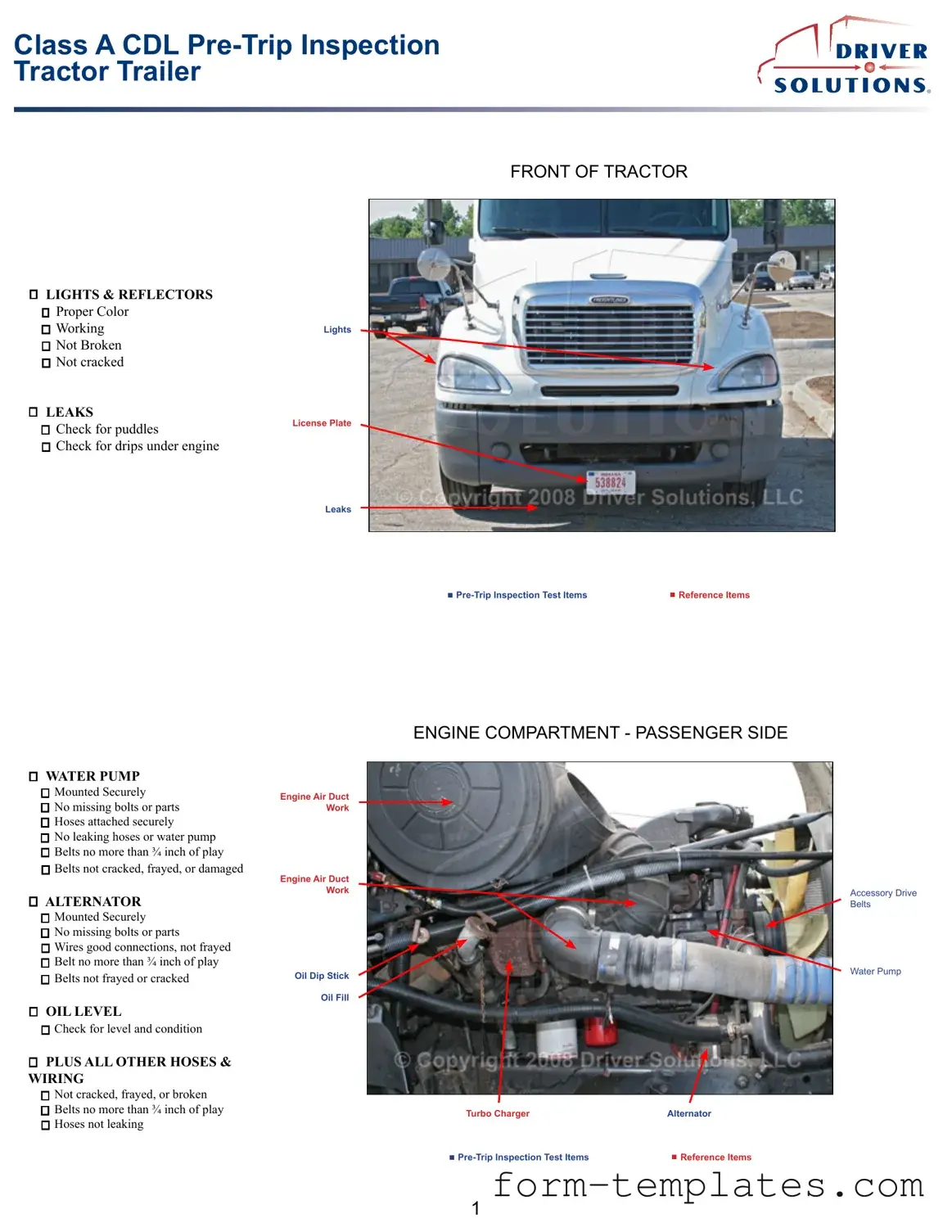

FRONT OF TRACTOR

LIGHTS & REFLECTORS o Proper Color

o Working

o Not Broken o Not cracked

LEAKS

o Check for puddles

o Check for drips under engine

Lights

License Plate

Leaks

Reference Items |

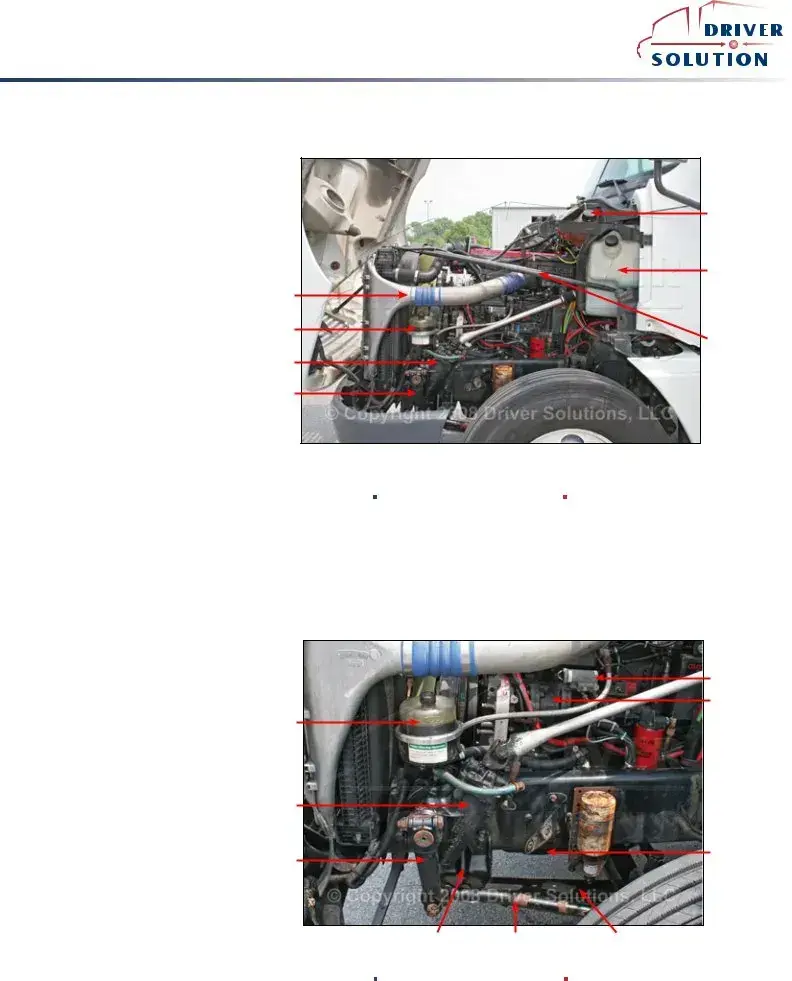

ENGINE COMPARTMENT - PASSENGER SIDE

WATER PUMP o Mounted Securely

o No missing bolts or parts o Hoses attached securely

o No leaking hoses or water pump o Belts no more than ¾ inch of play

o Belts not cracked, frayed, or damaged

ALTERNATOR

o Mounted Securely

o No missing bolts or parts

oWires good connections, not frayed

oBelt no more than ¾ inch of play

oBelts not frayed or cracked

OIL LEVEL

oCheck for level and condition

PLUS ALL OTHER HOSES & WIRING

oNot cracked, frayed, or broken

oBelts no more than ¾ inch of play o Hoses not leaking

Engine Air Duct Work

Engine Air Duct Work

Oil Dip Stick

Oil Fill

|

Accessory Drive |

|

Belts |

|

Water Pump |

Turbo Charger |

Alternator |

Reference Items |

1

Class A CDL

®

®

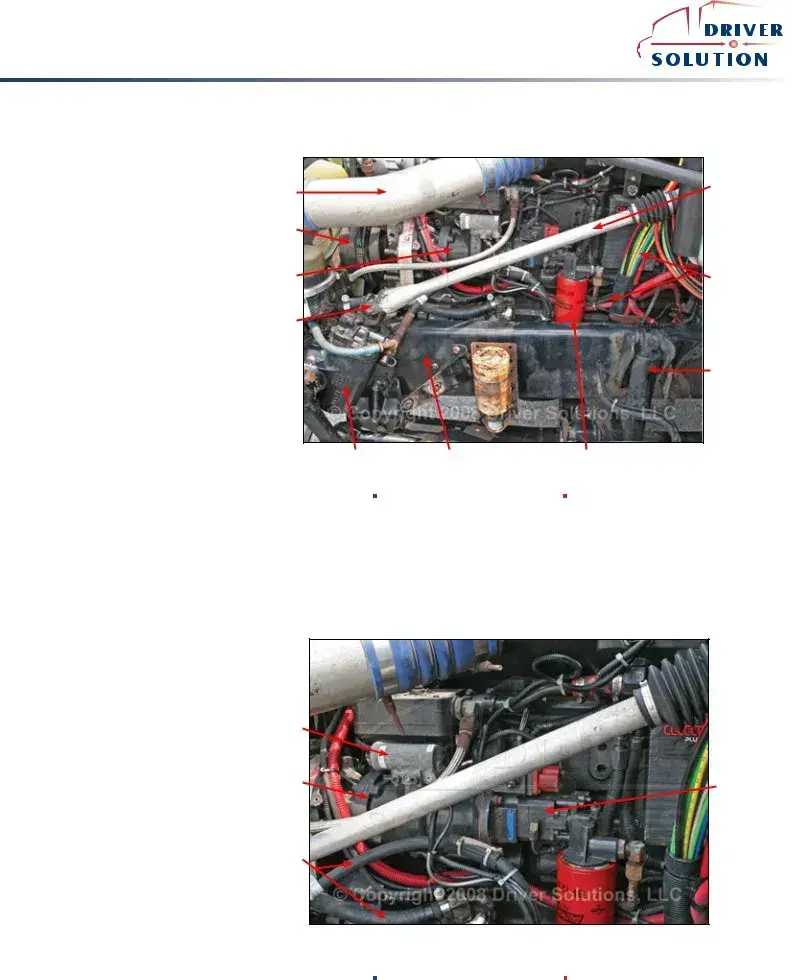

ENGINE COMPARTMENT - DRIVER SIDE

COOLANT

oCheck for level and condition

oHoses attached and not leaking

POWER STEERING RESERVOIR

oMounted properly

oHoses attached and not leaking

oCheck for level and condition

AIR COMPRESSOR

oMounted Securely

oNo missing bolts or parts

oNo air leaks at lines

oCheck if gear or belt driven

oBelt no more than ¾ inch of play

oBelts not cracked or frayed

STEERING GEAR BOX

oMounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

|

Engine Coolant |

|

Reservoir |

|

Windsheild |

|

Washer Fluid |

|

Reservoir |

Engine Air Duct |

|

Work |

|

Power Steering |

|

Reservoir |

Radiator Brace |

|

|

Steering Gear |

|

Box |

|

Pitman Arm |

|

Reference Items |

POWER STEERING RESERVOIR |

ENGINE COMPARTMENT - DRIVER SIDE CON’T |

||

|

|

|

|

o Mounted properly |

|

|

|

o Hoses attached and not leaking |

|

|

|

o Check for level and condition |

|

|

|

AIR COMPRESSOR |

|

|

|

o Mounted Securely |

Power Steering |

|

|

o No missing bolts or parts |

|

|

|

Reservoir |

|

|

|

o No air leaks at lines |

|

|

|

o Check if gear or belt driven |

|

|

|

o Belt no more than ¾ inch of play |

|

|

|

o Belts not cracked or frayed |

|

|

|

STEERING GEAR BOX |

Steering Gear |

|

|

Box |

|

|

|

o Mounted properly |

|

|

|

o No missing parts, nuts or bolts |

|

|

|

o Lines and hoses not leaking or |

Pitman Arm |

|

|

broken |

|

|

|

|

|

|

|

STEERING LINKAGE |

|

|

|

o Pitman arm, Drag link, Steering |

|

|

|

knuckle, Tie rods and tie rod ends |

|

|

|

o Not cracked, bent or broken |

Spring Mount |

Drag Link |

Leaf Spring |

o Castle nuts and cotter pins |

|

|

|

o Not missing and in place |

|

|

|

Reference Items |

Air Governor

Air Compressor

Engine Oil Pan

2

Class A CDL

®

®

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

STEERING GEAR BOX

o Mounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

ENGINE COMPARTMENT - DRIVER SIDE CON’T

Engine Air Duct

Work

Fan Belts

Gear Driven Air

Compressor

Steering

Steering Column

Additional Hoses & Wiring

Shock Absorber

Steering Gear Box |

Frame Rail |

Fuel Filter |

Reference Items |

||

ENGINE COMPARTMENT - AIR COMPRESSOR

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

Air Governor

Gear Driven Air Compressor

Hoses

Fuel Pump

Reference Items |

3

Class A CDL

®

®

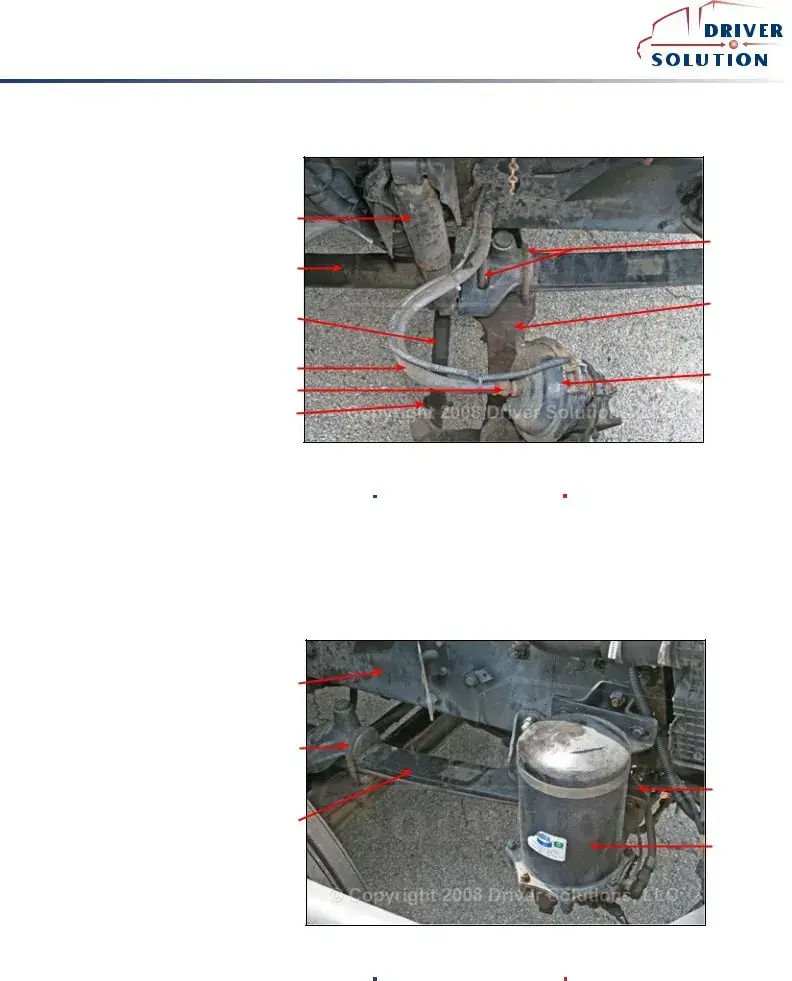

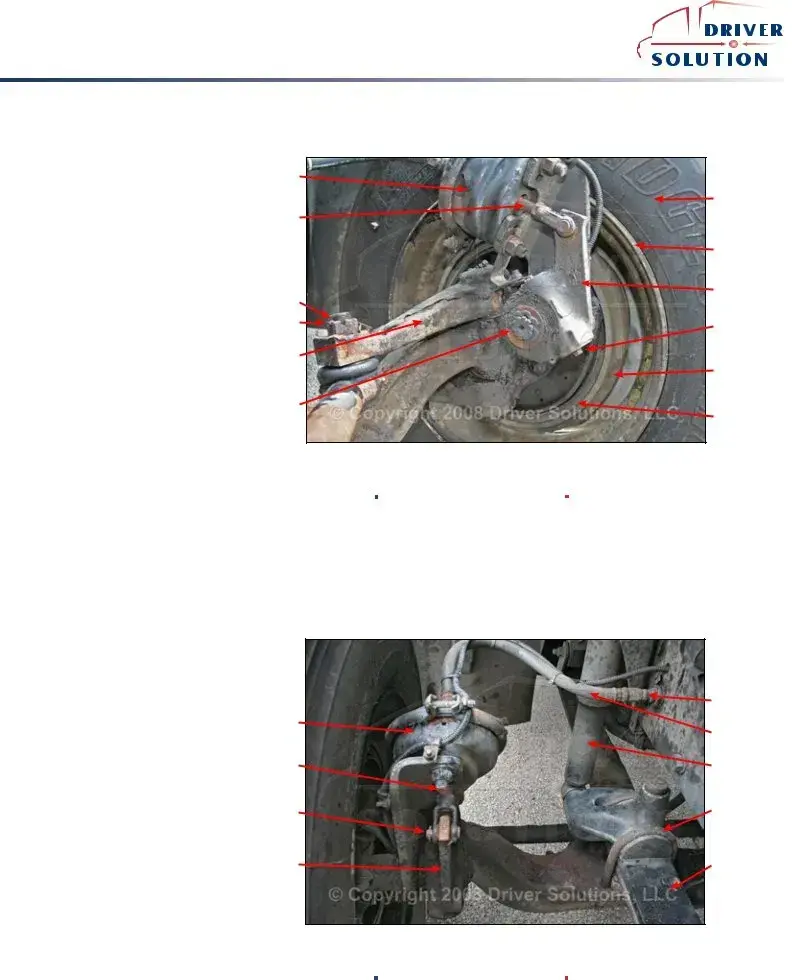

FRONT SUSPENSION

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

Shock Absorber

Leaf Spring

Tie Rod

Air Hose

Air LIne

Tie Rod End

Axle |

Service Brake |

Chamber |

Reference Items |

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

FRONT SUSPENSION CON’T

Frame Rail

Leaf Spring

Air Dryer location varies depending on model.

Located either behind the front bumper or behind the fuel tank.

Reference Items |

4

Spring Mount

Air Dryer

Class A CDL

®

®

HOSES AND LINES |

|

FRONT BRAKES |

|

|

|

||

o Mounted securely |

Service Brake |

|

|

o |

Not leaking |

|

|

o |

Not cracked or frayed |

Chamber |

|

|

Tire |

||

|

|

|

|

CHAMBER |

Push Rod |

|

|

o Mounted securely |

|

|

|

o Not dented or damaged |

|

Wheel |

|

o |

Not leaking |

|

|

SLACK ADJUSTER |

|

Slack Adjuster |

|

o |

No more than 1 inch of free play at |

Castle Nut |

|

the push rod with the brakes released. |

Cotter Pin |

Adjustment Nut |

|

o |

Not bent, broken, loose, or missing |

|

|

|

|

||

parts |

Steering |

|

|

|

|

Knuckle |

Brake Drum |

DRUMS |

|

||

|

|

||

o |

Not cracked, broken or dented |

|

|

o |

No oil leaking from inner oil seal, |

Snap Ring |

|

free of debris |

|

Brake Lining |

|

LININGS |

|

|

|

oNo cracked, broken or missing parts o Not less than ¼ inch in thickness

Reference Items |

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNot bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

FRONT BRAKES CON’T

Service Brake

Chamber

Push Rod

Clevis Pin &

Cotter Pin

Slack Adjuster

Reference Items |

Air Line

Air Hose

Shock Absorber

Spring

5

Class A CDL

®

®

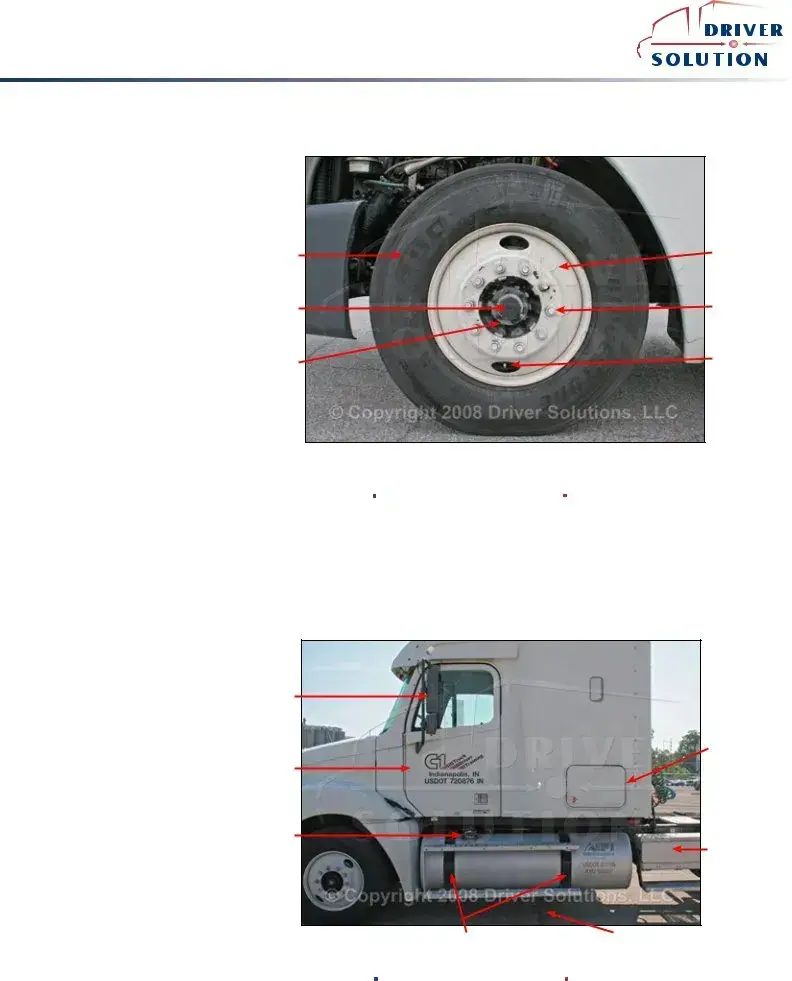

FRONT WHEEL

TIRES

oProper inflation – company or manufacturer specification

o No bulges, cuts, or retreads

o Minimum tread depth of 4/32”

RIMS

oNot bent, cracked, No welding repairs.

LUG NUTS

oNone are missing

oTight – no shinny threads, or rust trails

OUTER HUB OIL SEALS

oNot leaking, no missing bolts o Proper oil level

Tire |

Wheel |

|

Hub Oil |

Lug Nut |

|

Reservior |

||

|

||

Outer Hub |

Valve Cap |

|

Oil Seal |

|

Reference Items |

DRIVER FUEL AREA

DRIVER’S DOOR

oDoor opens and closes properly

oSeal is in good condition

DRIVER’S MIRRORS

oClean and free of obstruction

oNot cracked, broken, or damaged

oMounted securely

FUEL TANK

oMounted securely

o Not leaking

o Seal in cap OK

Mirror |

Storage |

Compartment |

Door |

Cap & Seal |

Battery Box & |

Cover |

Saddle Mounts |

Leaks |

Reference Items |

6

Class A CDL

®

®

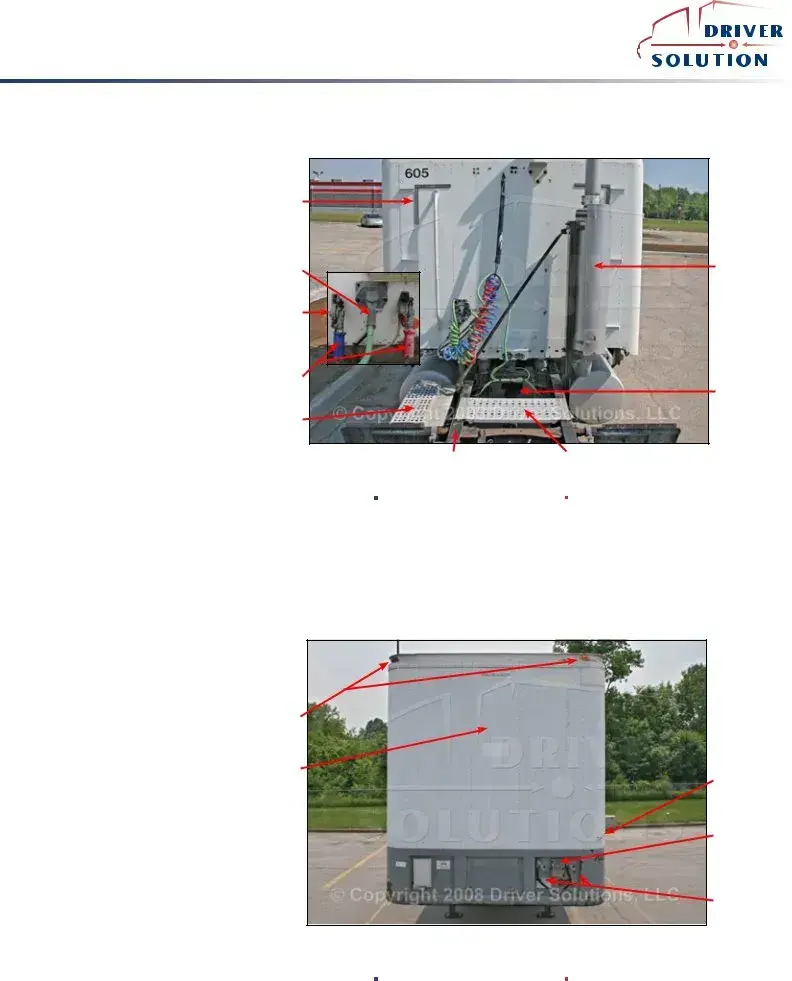

AIR LINES & ELECTRIC LINE o Not cracked, frayed, cut, or kinked o Mounted securely at the glad hands o Not leaking

BEHIND THE CAB

BATTERY BOX & BATTERIES o Box is mounted properly

o Batteries are secure in the box o Lid secure

o Connections not corroded

CATWALK

o Mounted properly

oNot, missing, or damaged

oFree of obstructions

DRIVE SHAFT

oNot bent, or damaged

oCoupling,

EXHAUST SYSTEM

oSecurely mounted

oNot dented or damaged

oNot leaking

FRAME

oNot cracked, or damaged

oNo missing bolts

oNo illegal welds

LIGHTS & REFLECTORS

oClean and working

Lights & |

|

Reflectors |

|

Electrical Line |

Exhaust |

Glad Hand |

|

Service & |

|

Emergency |

|

Airlines |

Drive Shaft |

|

|

Battery Box & |

|

Batteries |

|

Frame |

Catwalk |

Reference Items |

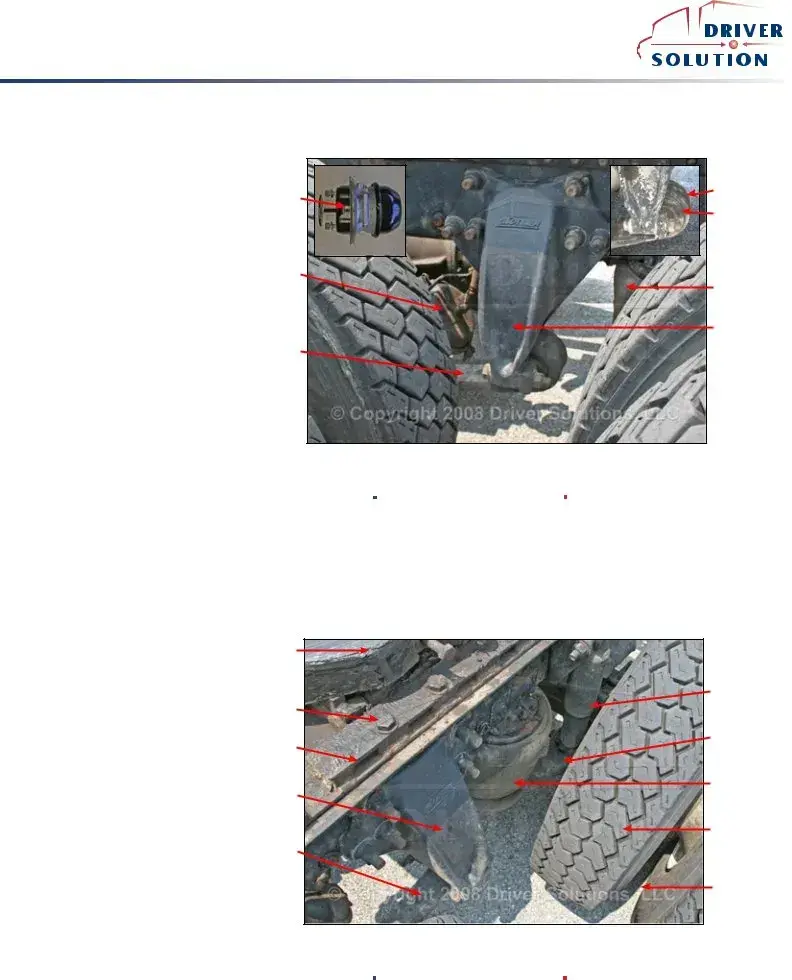

FRONT OF TRAILER

HEADER BOARD

oNo holes or missing rivets

LIGHTS & REFLECTORS

oNone broken, cracked, or missing

oWorking and proper color of amber

Lights |

Header Board |

Height Sticker

Electric Hookup

Air Line

Reference Items |

7

Class A CDL

®

®

DRIVE AXLE SUSPENSION

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Spring Brake |

Torsion Bar |

|

|

Chamber |

Control Arm |

|

|

Spring Brake |

|

Chamber |

Air Bag |

|

|

|

Control Arm |

|

Mount |

Control Arm |

|

Reference Items |

DRIVE AXLE SUSPENSION CON’T & FIFTH WHEEL

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Skid Plate |

|

|

Shock Absorber |

Mounting |

|

Bolts |

|

Locking |

Spring |

|

|

Pins |

|

Control Arm |

Air Bag |

|

|

Mount |

|

|

Tire |

Control Arm |

|

|

Space |

Reference Items |

8

Class A CDL

®

®

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNo bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

DRIVE BRAKES & DRIVE SHAFT

Drive Shaft

Universal Joint

Differential

Reference Items |

Air Line

Service Brake Chamber

Frame

Brake Chamber Mount

Slack Adjuster

TIRES

oProper inflation - company or manufacturer specification.

o No bulges or cuts, can have retreads o Minimum tread depth of 2/32”

RIMS

oNot bent or cracked

oNo welding repairs

LUG NUTS

oNone missing

oTight – no shinny threads, or rust trails

OUTER AXLE SEAL

oNot leaking, no missing bolts

SPACE OR SPACER

oCheck for objects between wheels

oCheck for proper spacing

Lug Nuts

Outer Axle Seal

DRIVE WHEELS

Tire

Bud Rim

Dayton Rim |

Spacer |

Reference Items |

9

Class A CDL

®

®

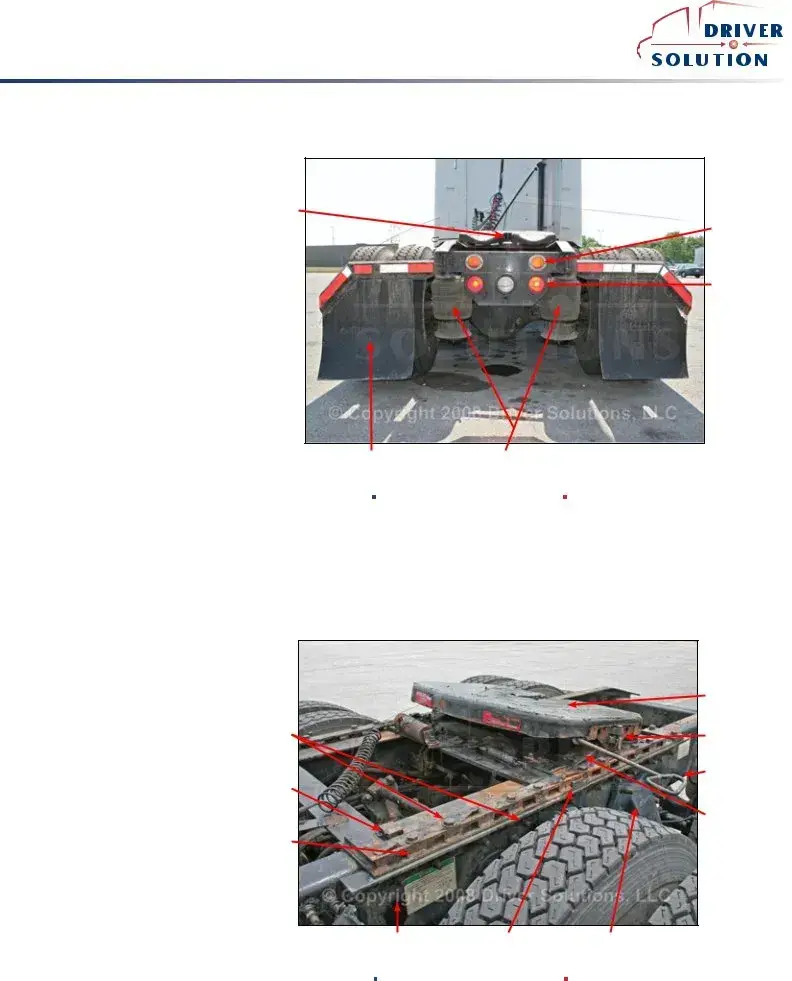

REAR OF TRACTOR

LIGHTS & REFLECTORS o Not cracked, or broken

o Working and proper color

SPLASH GUARDS

oNot missing or torn and properly mounted

Locking Jaws |

|

|

Reflectors |

|

Lights |

Splash Guard |

Air Bags |

Reference Items |

MOUNTING BOLTS

oNone missing or broken

RELEASE ARM

oNot bent, broken, or damaged

oEngaged in the lock position

LOCKING PINS

oNo missing or broken parts

oEngaged and locked

PLATFORM

oSecurely holds skid plate

oNot cracked, or broken

SKID PLATE

oMounted properly on the platform

oProperly greased

oTilting freely

Mounting Bolts

Slide Stops (all 4 corners)

COUPLING SYSTEM

Skid Plate |

Pivot Pin |

Release Arm |

Platform |

KING PIN |

Welds |

oNot broken, bent, or damaged

APRON

oNo bends or damage to visible portions

GAP

oCheck that the trailer apron is lying flat on the fifth wheel skid plate

Frame |

Slide Locking Pin |

Spring Mount |

JAWS |

Reference Items |

|

|

|

|

o Check that the locking jaws are fully |

|

|

closed around the shank of the king pin |

10 |

|